Coil-Fed Laser Blanking Technology has many benefits that can help you in your manufacturing processes. In this scenario, we evaluate a 32” diameter circular part, commonly found in the cookware industry. Our analysis is with a 60” wide, 0.030” thick stainless steel coil compared to sheets using traditional table lasers.

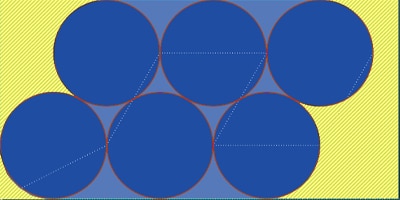

SHEET ANALYSIS (TABLE LASER) TECH

| Length | Part Quantity | Scrap % |

|---|---|---|

| 120″ (Standard) | 6 | 33.139% |

| 112.5″ | 6 | 28.681% |

COIL ANALYSIS (COIL-FED LASER)

| Length | Part Quantity | Scrap % |

|---|---|---|

| 1,637ft | 1,218 | 16.739% |

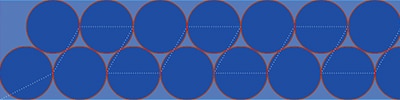

COIL ANALYSIS (COIL-FED LASER)

| Sheet Quantity | Weight | Length | Part Quantity | Scrap % |

|---|---|---|---|---|

| Coil-Fed1 (Continuous Strip) | 10,000lbs | 1,637ft | 1,218 | 16.739% |

| Sheet | 10,000lbs | 1,637ft | 978 | 33.139% |

Producing metal blanks using coil-fed laser blanking technology allows for greater material optimization, that will save you money. The savings in this scenario is 1,640lbs less scrap. The result is a 49.5% scrap improvement when utilizing coil-fed laser blanking technology. The ability to cut parts edge-to-edge from slit to width coils can result in even further savings in certain scenarios.

OUTCOME: SCRAP IMPROVES 49.5%

WHEN UTILIZING COIL-FED LASER BLANKING TECHNOLOGY

Scrap savings is one of the many advantages of using coil-fed laser blanking technology over traditional laser blanking methods.

To learn more about our coil-fed laser blanking solutions,

please fill out our Contact Form or give us a call at (630) 274-0600