- Call Now: 630-274-0600

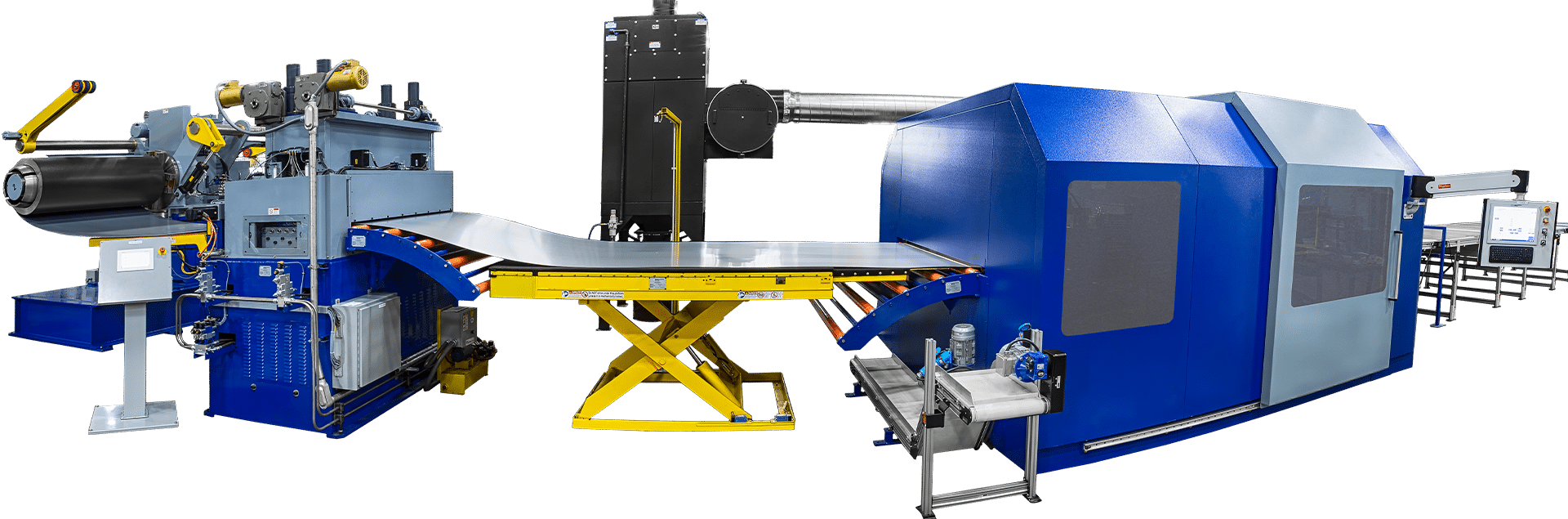

Laser cut parts continuously from coil

Seamless changeovers between designs, and the ability to produce multiple parts and configurations quickly. Eliminate the inefficiencies of dies, changeovers, maintenance and cumbersome storage.

No more limitations! Make design changes or updates at the speed of a mouse click. Process various material widths. Cut a range of materials including high strength steel and aluminum.

Clean, high-quality edges by eliminating flashback with an accurate 10kW fiber laser that cuts over open space using innovative mechanical slats that move with the laser head.

We are continuously innovating and producing the most efficient and dependable laser blanking equipment tailored to your manufacturing needs

Automatically separate parts from scrap and reduce material handling

Process sheets or coils in a range of material types and thicknesses up to 0.25"

Open air laser cutting eliminates flashback providing high-quality cuts on both sides of the part

Increase production with laser head speeds up to 98.4 in/ s and 2g acceleration

Hold tight part tolerances for demanding applications

Produce multiple parts and configurations with no die changeovers and higher yields

As part of The RDI Group, we’ve been using advanced engineering, creative design and industrial expertise to improve manufacturing processes for more than 115 years.

Complete machine shop in-house, with greater control on timeline, quality, processes, and procedures

The RDI Group has been providing coil processing equipment for over 45 years

Established organization with customers located globally in various industries

Partner for full lifecycle of your equipment. including service, support, replacement parts, & more