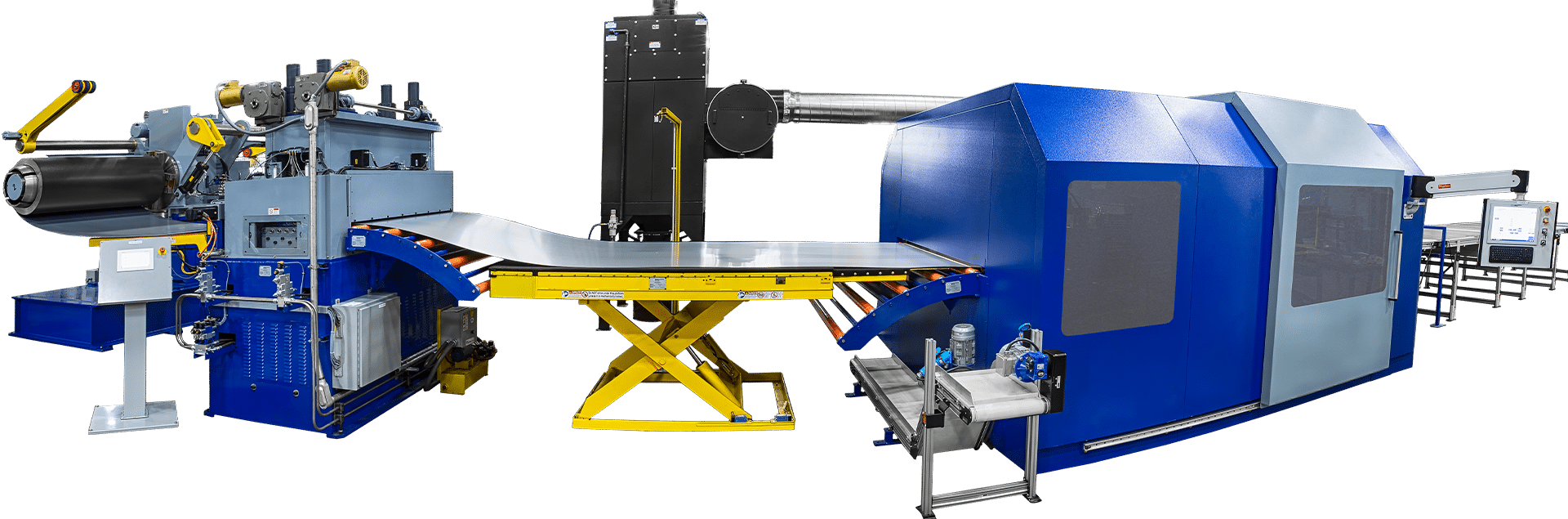

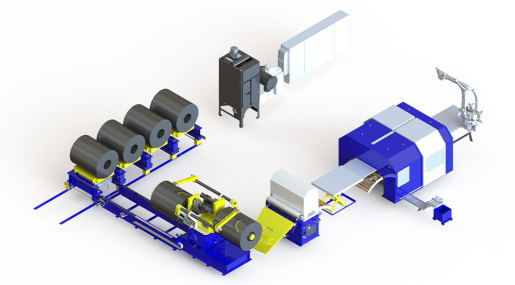

As the name implies, our coil-fed laser blanking lines allow manufacturers to produce parts directly from coils. The process consists of unwinding coils, correcting coil defects, and cutting configured blanks. System components include the uncoiler, strip correction, and precision fiber laser module. Finished part handling, an automation control system, and auxiliary equipment are also provided. These are mainly to assist in loading, feeding, and powering processes. After all, we are as committed to improving convenience as we are performance.