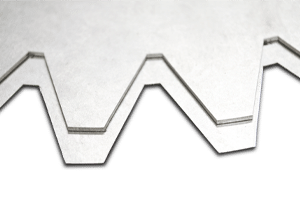

Designed with efficiency in mind, our coil-fed laser blanking technology continuously laser cuts parts from coils.

Continuous laser cutting is the ability to keep feeding material from the coil to the laser, so time is not lost waiting for material, giving the opportunity to maximize your laser cutting time.

The other option in the market today is an index mode feed. In this less optimized process, material is fed and then stopped, at which point the laser cuts the material.

Once the parts are cut, new material is fed in, and the process is repeated. Our goal has always been to reduce cutting time, eliminate white space, and provide overall quick times to process parts.

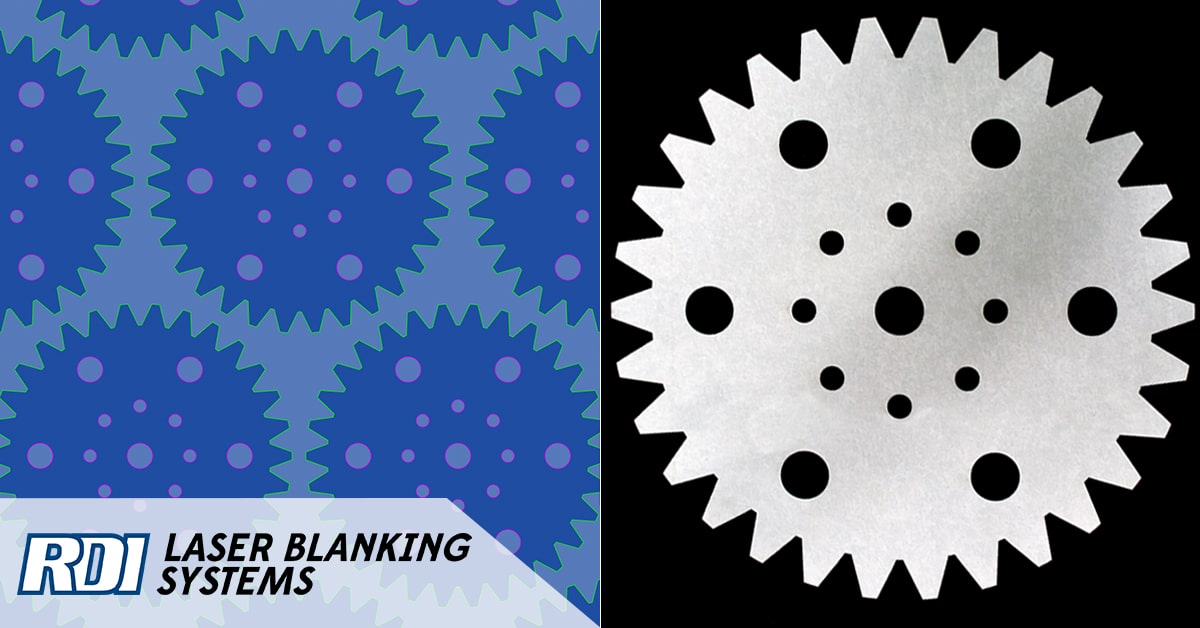

A common shape we come across in laser cutting is circles. In the video below, we laser cut 12” gears with ¾” and ¼” cutouts and demonstrate our technology’s capability to continuously laser cut parts.

About the Video

The laser cutting takes place with the material constantly moving. What takes place prior to the view of the video is the coil unwound from the uncoiler, and fed through the flattener for material flatness correction.

The complex gears are cut while still holding tolerances required for the application.

There is no need to index, or feed and stop the material to laser cut like a traditional table. The unnecessary time of this feed mode is eliminated with our continuous cutting process.

Our continuous cutting process paired with our open-air technology eliminates flashback while simultaneously allowing smaller scrap to fall on to a separate scrap conveyor. The gears go on to the main conveyor, while the smaller cutouts drop onto the scrap conveyor.

The days of wearing gloves, picking up scrap manually are over.

Let our automation take over the work for you.